Portable Gantry Cranes for Solar PV Workshops | 0.5–5 Ton Lifting Solutions

Portable Gantry Cranes in Solar PV Workshops: 0.5–5 Ton Flexible Solutions for Small-Scale Handling

Key Takeaways (at a glance)

- Portable gantry cranes provide low-cost, flexible lifting solutions for small-scale or modular solar PV workshops.

- Ideal for handling solar PV modules, inverter racks, frames, and auxiliary equipment.

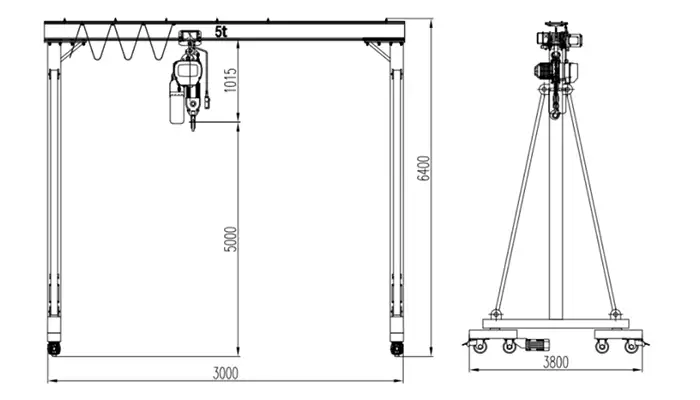

- Available in manual, semi-electric, and electric models, with capacities ranging 0.5–5 tons.

- Supports efficient workflow, safe lifting practices, and modular workshop layouts.

- Perfect for temporary, maintenance, or production tasks where fixed cranes are impractical.

Introduction

Handling solar PV modules, frames, inverters, and other components in small-scale workshops is often trickier than it looks. Many workshops don't have the space or budget for fixed overhead cranes, and moving heavy equipment by hand can be slow and unsafe. This is where 5 ton portable gantry cranes become a practical solution. They offer a mix of flexibility, cost efficiency, and quick deployment that fits the pace of small or modular solar PV operations.

These cranes are particularly useful when workshops need to:

- Adjust layouts frequently – Workstations can change based on production needs or maintenance tasks, and portable cranes move with them.

- Install equipment quickly – No need for complex runway beams or permanent structures. The crane can be set up in minutes.

- Lift safely without extra manpower – Even smaller modules or inverter racks can be heavy and awkward; these cranes take the strain off workers.

Typical portable gantry crane capacities range from 0.5 to 5 tons, which covers most small to medium solar modules and auxiliary equipment. This makes them ideal for:

- Lifting individual PV modules during assembly or inspection.

- Handling inverter racks, frames, and other workshop tools.

- Temporary or modular production setups where equipment layout changes often.

By integrating portable gantry cranes into the workflow, workshops can reduce manual handling, improve worker safety, and maintain a steady production pace without investing in expensive fixed cranes.

Why Portable Gantry Cranes Are Essential in Solar PV Workshops

Portable gantry cranes provide flexible, low-cost, and safe lifting solutions for solar PV workshops with limited space, modular layouts, or temporary assembly lines.

Flexibility and Mobility in Solar PV Workflows

Portable gantry cranes allow workshop teams to lift and position modules exactly where needed, adapting to changing layouts or tasks:

- Can be wheeled across the workshop floor without major setup

- Adjustable height and span to handle small, medium, and oversized solar modules

- Supports temporary lifting for module assembly, testing, and inspection

This flexibility is especially valuable in modular solar module assembly lines, where workstations are not fixed.

Cost-Effective Lifting for Solar PV Workshops

Portable gantry cranes deliver lifting capability without the heavy investment required for permanent cranes:

- Lower upfront cost compared to fixed cranes or hoists

- Minimal workshop modification required—no runway beams or structural changes

- Quick setup allows immediate use for lifting solar modules or inverter racks

By reducing capital costs, workshops can allocate resources to additional modules, testing equipment, or maintenance tools.

Safety and Ergonomics for Solar PV Teams

Portable gantry cranes reduce manual lifting risks, improving safety and precision in workshops:

- Lifts solar modules, inverter frames, and other components safely and efficiently

- Reduces repetitive strain injuries for assembly or maintenance teams

- Provides precise positioning for delicate PV modules, minimizing damage risk

Ideal for workshops where worker safety and product care are both critical.

Supports Modular and Small-Scale Solar PV Production

Portable gantry cranes adapt to temporary or modular setups, small batch production, and maintenance tasks:

- Adaptable to changing assembly lines or workstations

- Supports multiple lifting tasks—from module positioning to inverter handling

- Can be stored or relocated when not in use, keeping workshop space clear

By supporting modular production and maintenance, they help workshops stay flexible, efficient, and responsive to changing project requirements.

Types of Portable Gantry Cranes for Solar PV Workshops

The type of portable gantry crane you choose depends on module size, inverter weight, and workshop layout flexibility. Here's a practical guide to the main types used in solar PV workshops.

Manual Gantry Cranes

Manual gantry cranes are ideal for small workshops or lighter solar PV components. They operate entirely by hand, making them low-cost and easy to maintain.

- Handles components up to 0.5–1 ton

- No electricity needed, minimal maintenance

- Quick setup for multiple workstations

- Best for occasional lifts or smaller PV modules

Suitable for assembly stations, inspection areas, or maintenance bays where heavy lifting isn't constant but safety and precision matter.

Electric Gantry Cranes

Electric gantry cranes are used when workshops handle repeated lifting of heavier modules or inverter racks. Motorized travel and hoists improve speed, precision, and safety.

- Lifting capacity 2–5 tons, ideal for larger modules and inverter frames

- Motorized travel for smooth movement across the floor

- Electric hoist ensures precise placement, reducing risk of damage

- Best for workshops with frequent lifts or multiple assembly lines

They reduce strain on staff while improving efficiency and safety in high-volume tasks.

Adjustable Gantry Cranes

Adjustable gantry cranes provide flexibility for workshops with limited space or frequently changing layouts.

- Height and span can be modified for different module sizes and layouts

- Foldable designs allow easy storage and free floor space when not in use

- Supports multi-purpose operations, from assembly to testing or maintenance

Particularly useful in modular production lines or workshops that occasionally need to move cranes out of the way.

Practical Deployment Considerations for Solar PV Workshops

Proper deployment of portable gantry cranes ensures smooth workflow, safe lifting, and efficient use of space in solar PV workshops. Key factors to consider include layout, capacity, mobility, and safety.

Floor Space & Layout Planning

Clear pathways and smart layout are essential for safe and efficient crane operation.

- Keep aisles and travel paths free of obstructions such as pallets, tools, or racks

- Maintain designated safety zones around the lifting area

- Consider module sizes, workstation layout, and workflow patterns when positioning cranes

- Ensure sufficient vertical clearance for modules, inverter racks, and tall components

Proper layout allows efficient module movement, reduces downtime, and prevents accidents.

Capacity Planning & Duty Cycle

Understanding load and usage frequency is crucial for safe and reliable operations.

- Calculate maximum lift load, including a 10–20% safety margin for variations

- Consider lifting frequency for semi-electric and electric cranes to match duty cycles

- Ensure crane capacity matches the heaviest PV modules or equipment handled regularly

Accurate capacity planning protects both personnel and modules.

Mobility & Storage

Planning for crane mobility and storage maximizes flexibility in modular workshops.

- Use wheeled cranes for easy relocation between workstations

- Consider foldable or collapsible designs for storage when not in use

- Position cranes so they don't block workflow or emergency exits

Mobility planning enables quick reconfiguration of assembly or maintenance stations without disrupting tasks.

Safety Measures

Safety practices are essential to protect staff and prevent damage to PV modules and inverter equipment.

- Train operators on safe lifting practices, load handling, and emergency procedures

- Inspect cranes regularly: hoist, frame, wheels, bolts, and safety components

- Maintain a log of inspections and repairs

- Follow local safety regulations and workshop guidelines for all lifting operations

Use Cases in Solar PV Workshop Operations

Portable gantry cranes are essential tools in solar PV workshops, supporting assembly, maintenance, temporary production lines, and equipment handling. They improve safety, precision, and workflow efficiency.

Module Assembly & Alignment

Portable gantry cranes help lift and position PV modules accurately during assembly, reducing damage and worker fatigue.

- Move PV modules safely to assembly stations or workbenches

- Adjust height and span for proper alignment

- Reduce manual handling and worker fatigue

- Enable one or two operators to position modules efficiently

Using cranes for assembly increases productivity and minimizes module breakage.

Maintenance & Repairs

Portable gantry cranes provide a safe and controlled way to lift components for maintenance or repair tasks.

- Lift inverters, frame assemblies, or auxiliary components for servicing

- Hold equipment in position for precise work

- Minimize the risk of injury to personnel

- Ideal for workshops with limited space or changing layouts

Cranes make maintenance faster, safer, and less disruptive to other operations.

Temporary Production Lines

Portable gantry cranes support flexible or small-batch production setups in modular workshops.

- Support modular or small-batch solar module production

- Relocate cranes quickly between workstations as production shifts

- Provide lifting capability for temporary assembly, testing, or packaging areas

- Facilitate workflow changes without costly infrastructure adjustments

This ensures workshops can scale operations efficiently and safely.

Equipment Handling

Beyond modules and inverters, portable gantry cranes assist with auxiliary equipment handling to maintain organized workflows.

- Transport auxiliary equipment between workstations or storage areas

- Reduce clutter and manual lifting on the workshop floor

- Keep workflow continuous and safe

- Useful for workshops handling multiple product lines or testing stations

These cranes become a central part of daily solar PV operations, supporting both assembly and maintenance efficiently.

Buyer Checklist: Selecting the Right Portable Gantry Crane for Solar PV Workshops

This checklist helps engineers, maintenance teams, and planners choose the right portable gantry crane, ensuring safe, efficient, and cost-effective solar PV workshop operations.

Determine Maximum Lifting Capacity

- Identify the heaviest module, inverter rack, or auxiliary equipment your workshop will handle

- Include a safety margin of 10–20% for weight variations or unexpected loads

- Typical capacities for solar PV workshops range from 0.5–5 tons, covering most small to medium module handling needs

Choose the Right Crane Type

- Manual Gantry Cranes: Ideal for occasional lifts of light modules (0.5–1 ton). No electricity needed and minimal maintenance

- Electric Gantry Cranes: Motorized travel and hoist. Best for repeated handling of heavier modules (2–5 tons)

- Select based on workflow speed, lifting frequency, and available operators

Assess Adjustable Height and Span

- Ensure the crane can adapt to different module sizes and workstation layouts

- Adjustable or telescopic designs provide flexibility for assembly, maintenance, or testing tasks

- Foldable options are useful for workshops with limited space or temporary setups

Ensure Floor Clearance and Mobility Paths

- Confirm that aisles, floors, and pathways allow safe crane movement

- Consider wheel design and ability to navigate around workstations without obstruction

- Keep emergency exits, equipment racks, and high-traffic zones clear for smooth workflow and safety

Check Duty Cycle, Safety Compliance, and Maintenance Needs

- Verify that the crane's duty cycle matches your lifting frequency, especially for electric models

- Ensure compliance with local safety standards and workshop regulations

- Schedule regular inspections of hoists, structural frames, and wheels to maintain reliable performance and safe operation

Evaluate Budget vs. ROI

- Consider total cost including purchase, setup, and ongoing maintenance

- Factor in labor savings, reduced manual handling, and less risk of module or equipment damage

- A well-chosen crane should improve workflow efficiency and pay for itself through safer, faster operations

Conclusion

Key Takeaways:

- Flexible and Cost-Effective: Portable gantry cranes provide workshops with lifting solutions that adapt to changing layouts and tasks without expensive installation.

- Capacity Range: Suitable for handling small to medium solar modules and equipment, with capacities from 0.5 to 5 tons.

- Versatile Applications: Ideal for small-scale handling, modular production lines, and maintenance operations in solar PV workshops.

- Workflow Efficiency: Choosing the right crane type and capacity, combined with proper layout planning, ensures smooth operations and reduced downtime.

- Safety and Ergonomics: Reduces manual lifting, minimizes risk of injury, and protects delicate modules, making operations safer for engineers and maintenance teams.

Why It Matters for Solar PV Workshops:

Portable gantry cranes are more than just lifting tools. In small-scale or modular workshops, they enhance productivity, improve safety, and simplify material handling. With the right selection and setup, these cranes become an indispensable part of daily operations, helping workshop teams handle solar modules and equipment efficiently and safely.

Questions Solved Here

This section addresses common concerns for solar PV workshops, helping engineers and maintenance teams choose the right crane, plan layouts, and ensure safe operations.

1. Best Portable Gantry Crane for Small-Scale Solar PV Handling

- Manual cranes: Light modules (0.5–1 ton), occasional lifts, minimal maintenance

- Electric cranes: Heavier modules (2–5 tons), frequent handling, precise positioning

- Adjustable/foldable cranes: For workshops with variable layouts or multi-purpose stations

2. Selecting the Right Lifting Capacity and Duty Cycle

- Identify the heaviest PV module, inverter rack, or auxiliary equipment

- Include a 10–20% safety margin for unexpected weight variations

- Consider duty cycle requirements, especially for repeated lifts in electric cranes

3. Layout and Mobility Considerations for Efficiency and Safety

- Keep aisles and pathways clear for crane travel

- Ensure vertical and horizontal clearance for modules and racks

- Use wheeled or foldable cranes if workstations change frequently

4. Matching Crane Types to Modular Production and Maintenance Tasks

- Manual cranes: Occasional lifts or small workshops

- Electric cranes: Frequent lifting in modular production lines or maintenance operations

- Adjustable cranes: Flexible for multi-purpose tasks and varying module sizes

5. Practical Safety and Maintenance Tips

- Train operators on safe lifting and load handling practices

- Inspect hoists, wheels, structural frames, and bolts regularly

- Keep a maintenance log and follow local safety regulations